5 operational excellence pitfalls to avoid in high-risk work

Operational excellence means safe, efficient, predictable operations. In high-risk industries, outdated permit to work management systems often become the biggest bottleneck. Paper forms and siloed approvals leave crews idle, projects late, and near-misses become major incidents.

When high-risk work coordination breaks down, the consequences go beyond compliance violations. Downtime, productivity, consistent performance, and human lives are impacted. Shifting to modern safety permit software ties safety checks into everyday workflows, preventing the delays and hidden hazards of paper processes.

Below, we explore five common pitfalls that undermine operational excellence in high-risk work and how digital permit to work software can fix them.

Table of contents

Click on a specific section below to navigate to that area:

1. Treating safety as separate from operations

When safety is seen as a checkbox rather than integral to production, workers often bypass procedures to keep schedules on track. This misalignment between safety and operations leads to shortcuts and inconsistent compliance, dramatically increasing risks. Neglecting a permit or skipping a lockout/tagout step can turn a near-miss into a costly accident.

The fix: Rethinking how safety approvals flow through work processes. Digital safety permit software integrates safety controls directly into operational workflows, making compliance a natural step rather than an afterthought. Instead of separate signoffs, digital permit to work systems lock in safety controls (training, risk assessments, isolations) automatically whenever work is requested.

For example, permit to work software enforces that required checks (like LOTO or atmosphere tests) are completed before a permit is issued. In other words, instead of treating safety as an obstacle, the software embeds it seamlessly into daily operations so workers can’t skip it.

2. Paperwork that slows down work

Paper-based permit systems create a paradox: they’re designed to improve workplace safety, yet their inefficiency drives the very corner-cutting they’re meant to prevent. Permits get lost between shifts. Handwritten approvals become illegible. Sign-offs require physically tracking down supervisors across multiple locations, leaving contractors idle and equipment sitting unused.

Consider what one hour of unplanned downtime costs your business, not just in lost production, but in rescheduling contractors, extending outages, and the ripple effects across your operation. When paper permits delay work authorisation, costs accumulate quickly.

Building a business case for Permit to Work software is easier with this guide 👇

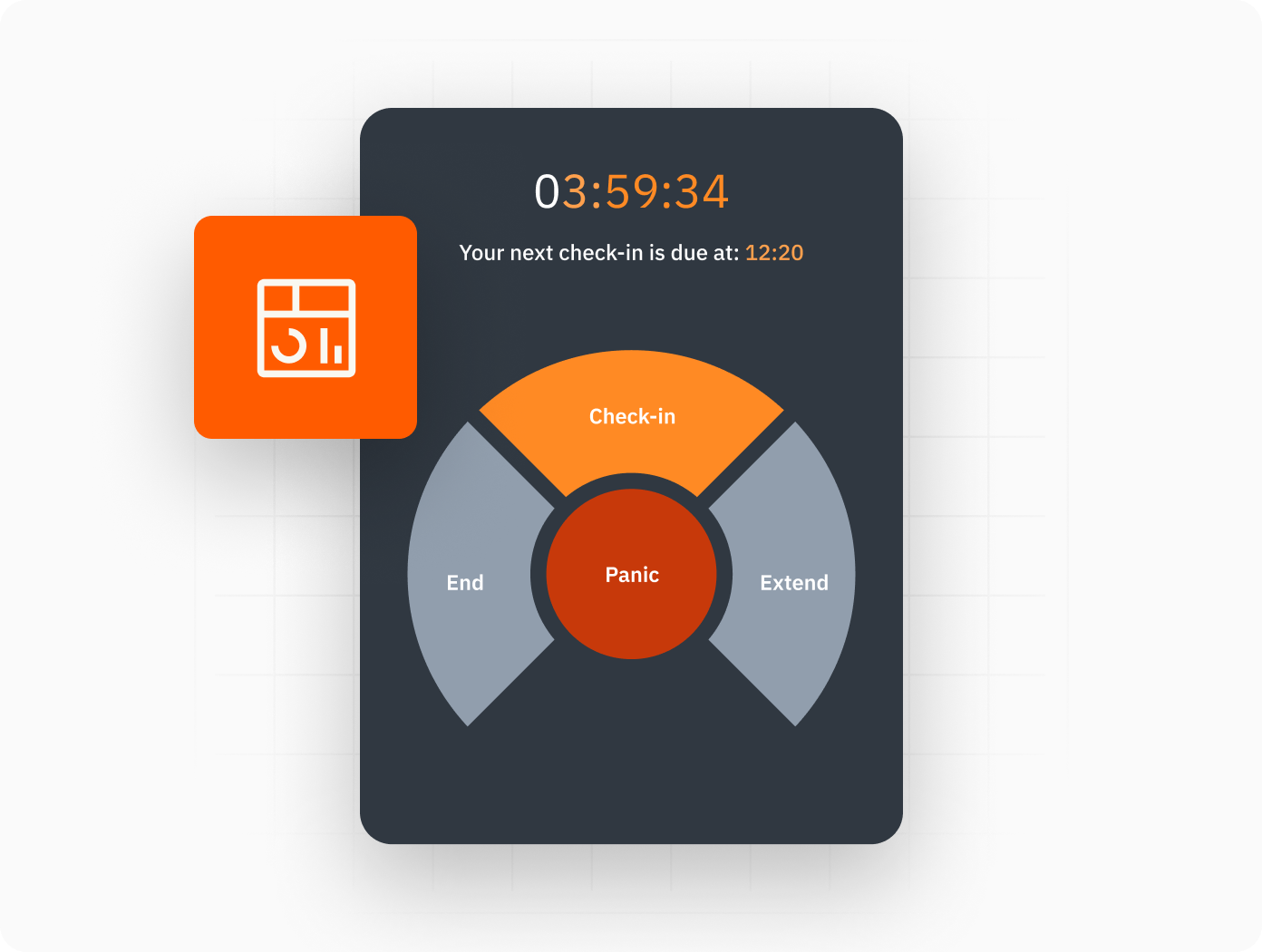

The fix: A digital permit to work platform centralises safety forms and approvals in one interface. Workers submit requests online and the system enforces the correct sequence of checks. Authorisers get instant alerts and can approve, or review permits from any device. This eliminates handoffs and bottlenecks. With control of work software, managers don’t have to hunt for signatures, they simply tap “approve” and the work can proceed. The result is more uptime and less wasted labour.

3. Poor visibility of what work is happening where

In complex facilities, multiple work activities often occur simultaneously. Hot work near flammable materials. Confined space entry adjacent to crane operations. Electrical isolation while chemical transfers continue nearby. These simultaneous operations, or SIMOPS, create risks that don’t exist when each activity happens in isolation.

The problem is visibility. With paper permits, site managers usually see a backlog of past jobs without a live map of ongoing high-risk work. They can’t mitigate risks because they don’t even know that they exist.

The fix: Real-time oversight through digital dashboards. Modern permit systems provide dashboards and calendars of all active permits. These tools flag any conflicting tasks before they start. The software can automatically detect SIMOPS conflicts, warning planners if a new permit overlaps a hazardous area. For example, halting a hot-work job if it’s scheduled near a pending chemical operation. This visibility prevents clashes and unplanned downtime.

4. Assumptions that controls are being followed

One of the most dangerous phrases in high-risk operations is “we always do it this way.” Without verification mechanisms, organisations operate on assumptions: that lockout/tagout was completed properly, that gas testing confirmed safe atmospheres, or that isolation procedures were fully executed.

Lack of proof creates uncertainty. On paper, someone may sign off but there’s no record beyond a name. Contractors under schedule pressure may skip steps, and organisations have no easy way to verify.

The fix: Require evidence. Digital permit systems force workers to prove they did each control step. For example, the software can demand a photo of a tagged isolation or a certified tester’s log before it releases the permit. This means a permit cannot be issued on “blind faith.” Every person’s qualification, every lockout installation, and every hazard control must be confirmed in the system.

The result is that safety checks are enforced by code, not by chance. Managers see a timestamped audit trail, not just a signature, so they know exactly what controls were completed. This closes the loopholes that paper can’t.

5. No data for performance improvement

Paper permits disappear into filing cabinets and take operational intelligence with them. Questions that should drive continuous improvement remain unanswered: Which activities generate the most permit cycle time? What percentage of permits require modification after initial submission? Where do approval bottlenecks occur? How often does high-risk work extend beyond authorised timeframes?

A stack of paper says nothing about performance. Without data, managers can’t pinpoint where delays or risks cluster, so inefficiencies persist. You can’t fix what you can’t measure.

The fix: Turn permit to work into a data source with the future of permit to work software. A digital permit system automatically logs all activities and enables KPI tracking. Electronic permits generate rich analytics: approval times, backlogs, workload by team and task, close call reports, and more. Operations leaders can track KPIs and pinpoint where to improve. These analytics reveal trends and leadership can then target training or process changes accordingly.

The path to operational excellence

Achieving operational excellence in high-risk industries requires more than incremental improvements. It demands fundamentally rethinking how organisations authorise, coordinate, and improve. The common thread connecting all five pitfalls is fragmentation.

EcoOnline’s permit to work software centralises control, automates approvals, and enforces compliance in real time. Organisations that bridge the gap between safety and productivity unlock continuous improvement which is the hallmark of operational excellence.

Want to see how all the different solutions stack up?

Compare ePermits vs SafetyCulture, Intelex, and EHS Insight 👇

About the author

Stephanie Fuller

Content Writer