Taking a technology-led approach to permit to work

When an organisation is managing high risk activities – such as construction projects, maintenance work, equipment installation and refurbishment – it is imperative that any work undertaken by a contractor is controlled to reduce the risk of injury, damage to property or assets and to make sure that operations are not disrupted or safety compromised.

Health and Safety Executive statistics show that in 2020/21, 38% of worker fatal injuries were to self-employed workers even though they made up only 16% of the workforce. The proportion of fatal injuries to self-employed workers is higher in 2020/21 than in earlier years: in the 5-year period 2016/17-2020/21, 31% of fatal injuries were to self-employed workers.

Your organisation and the contractors you use have responsibilities under health and safety law to make sure the right precautions are in place to reduce the risks of workplace dangers across the supply chain. Every organisation, large or small, needs to bring health and safety to the forefront to mitigate the risk from hazards such as COVID-19 and quickly and confidently work with contractors.

At the same time, increasing legal requirements and expectations from consumers, customers, employees and stakeholders, contractor management now goes beyond the more traditional and longer-recognised risks to include the wider aspects of Environment, Social and Governance (ESG) factors.

Non-compliance could cause significant brand and reputational damage resulting in significant negative publicity and fines. So, it’s important to check your contractors for ethical and wider ESG factors such as finances, modern slavery, anti-bribery, GDPR, quality and environment compliance.

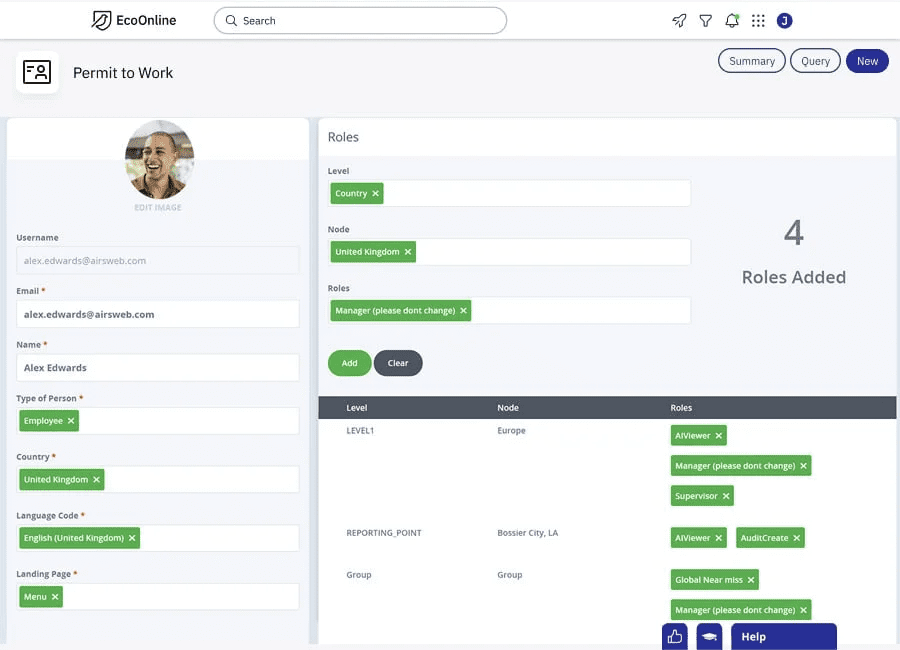

Digital Permit to Work

With a Permit-to-Work (PTW) process, organisations can effectively manage the compliance of those coming on site to perform their tasks, authorising them to carry out the work under strict controls. Traditional, paper-based, PTW systems can take a long time while permits are created, risk-assessed, handed over and implemented. By digitising the PTW process, organisations can save time and eliminate errors like inaccurate information and the risk of miscommunication.

In most areas of business, we’ve embraced technology that enables us to electronically store documents, manage processes and communicate more easily. With a fully integrated digital contractor management platform that provides one true view, organisations are better placed to make informed decisions and take positive action.

Helen Jones, Chief Operating Officer:

“Through real-time insights and digitised manual processes to connect people, processes and data, a technology-led approach can help to understand what drives contractor risk. With insight, streamlined processes and continuous improvement, organisations can drive greater control and increased visibility.”