Skill Decay: How To Keep Employee Training Fresh

We’ve already looked at how training mismanagement can cost your business money, but what about allowing skills to become forgotten over time?

The Health and Safety at Work Act expects employers to provide “such information, instruction, training, and supervision as is necessary to ensure, so far as is reasonably practicable, the health and safety at work of employees.”

The Management of Health and Safety at Work Regulations remind us that the training should be provided at recruitment, on being exposed to new or increased risks (for example, when new equipment is introduced or a job role changes) and should be “repeated periodically where appropriate.”

So how often is “periodically” and when is it “appropriate”? This question cannot be answered unless you first understand the training need, and to do that you need to define the job.

Case study

Anya is about to start work at the Caxton Copies printing company. The safety manager sits down with the person who will be her supervisor, and they write a list of all the things she will have to do. For simple tasks – like using the photocopiers – a demonstration from her manager will be enough, along with warnings not to do any maintenance tasks until she has been trained.

Complex tasks such as using the powered paper-cutting guillotine will need to be considered in more detail – daily pre-use checks, how the controls work, safe working practices required, and so on. The list references the detailed training programme for the guillotines. Anya will also need to handle boxes of paper and finished products, so manual handling and using the trolleys they have available is added to her list.

Then there are the things that aren’t “tasks” but still need to be covered – rules about storing food in the shared fridge (no rancid milk or mouldy cucumbers to be left over the weekend); information about spotting and reporting slip and trip hazards, and of course the fire and evacuation procedures.

The list might look something like this:

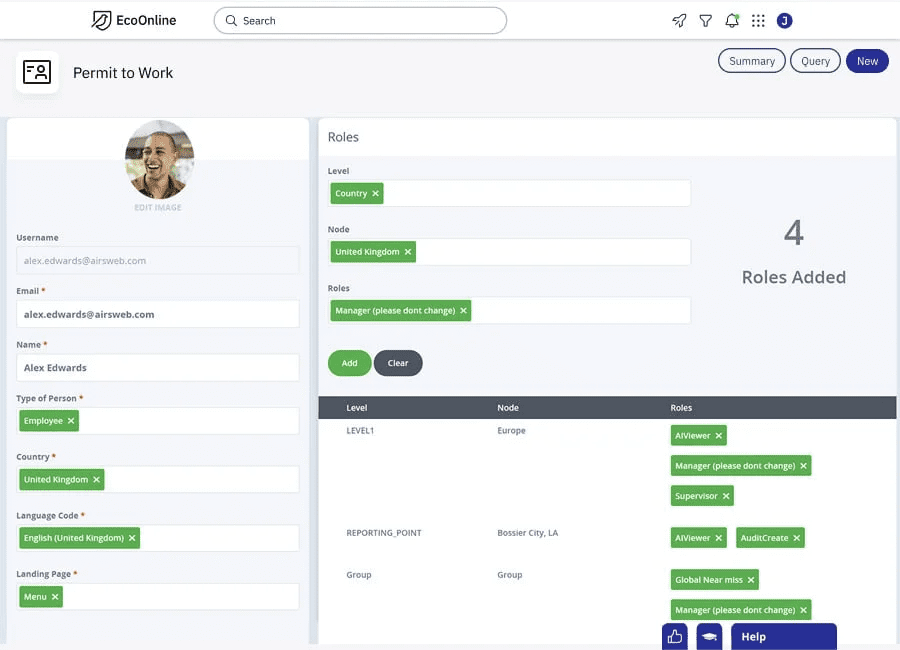

You could have this on paper, and sign off by hand, or add each training topic to an online training record system and log completion that way.

By the end of the first week, Anya is confidently photocopying, and calls a technician when the toner needs to be changed; she’s happy moving small loads by hand; she reported a leak coming from under the fridge, and when she heard the fire alarm, she knew what to do.

In week 2 she was shown how to use a large roll cage and a smaller trolley and was signed off as competent. Over the next few weeks, she used the smaller trolley nearly every day and remembered how to check it, not to overload it, to plan her routes.

A few weeks later she came to use the large roll cage. It jammed as she pulled it out of its space, but with some tugging, she got it out and took it to the print shop. It seemed much harder to manoeuvre than the smaller trolley – she assumed that was down to the weight. She didn’t know that it was damaged. Once it was loaded high with boxes of calendars to wheel down to the loading bay it was even more difficult to move. She pushed and pulled, and then it fell onto her legs, causing multiple fractures, and several weeks off work.

What had happened? It all started so well. The problem is, we forget what we have learnt unless it is refreshed. For tasks people do all the time, the learning is refreshed every time they do it – although periodically it is a good idea to check that bad habits haven’t crept in that could result in an accident. For tasks we do infrequently, we forget much more quickly than people might think.

Learning and forgetting curve

The learning and forgetting curve shows how when we first start learning, we quickly become more knowledgeable or more skillful. Over time it becomes more difficult to take new information in, and we need a break (the top of the blue curve). Then we start to forget, quickly at first, then more slowly as time goes on. The green line shows the minimum we need to know to do something safely and effectively – we overlearn initially because we will forget.

If we refresh the knowledge before we have forgotten too much, we can cause our efficiency to peak again (the purple curves). The more often we do that, the less likely we are to lose our competence. The red line shows the day of the accident – for Anya, the purple curves show that repeated use of the smaller trolley meant that on the day of the accident she was still competent. The blue line shows where she was with the roll cage.

To decide how often to re-train you need to consider the tasks people do, the competency needed – and the consequence if it goes wrong. Some alternative strategies to a “one size fits all” annual refresher training programme include:

- Risk-based: Are there some skills that are more important to protect people than others?

- Competence-based: For skills, observe people doing a task to see how much training they need, for knowledge, have a quiz, and only those who don’t score full-marks need to additional training.

- Experience-based: As the graph shows, each time you refresh your learning, the forgetting curve is less steep. If it was important for Anya to know how to check the roll cage for faults, she could have been shown weekly to start with, then monthly, then eventually annually.

- Training little and often, via on-the-job toolbox talks can be more effective than day-long annual refreshers in a classroom.

E-learning is another way to let people pace their learning – but remember to follow up with assessing competence on the job. Keeping track of employee training is very important for your business for compliance reasons.

Take a look at EcoOnline’s training management software to see how you can schedule and manage employee training while also cutting down on admin time.