What is a workplace exposure limit?

In a recent UK court case, a private healthcare provider was fined £160,000 after three employees were exposed to chlorine gas.

An HSE investigation found that the maximum volume of gas produced during the incident was nearly 8000 times over the workplace exposure limit. This level of exposure can be fatal within minutes.

Chemical agents are present in most workplaces and industries. As they are so commonplace, employers in the UK and EU must adhere to strict regulations controlling the amount of these substances that are present in the air. To protect workers’ health, organisations must ensure that hazardous substances fall below these limits.

In the UK, these regulations are known as ‘Workplace Exposure Limits (WELs),’ with the EU equivalent being ‘Occupational Exposure Limits’ (OELs).’ In the US, you will also encounter the terms ‘Threshold Limit Values’ (TLVs) or ‘Recommended Exposure Limits’ (RELs).

At their most basic, exposure limits provide a level of admissible exposure, over a specified length of time, to a chemical or physical hazard that is unlikely to harm the worker.

They are usually expressed as a concentration measurement such as parts per million (ppm), milligrams per cubic meter (mg/m³), or micrograms per cubic meter (µg/m³).

Dealing with the acronym-heavy world of exposure limits can be difficult to wrap your head around. In this blog post, we are going to take a closer look at what they are, associated terms and definitions, and employer best practices around exposure reporting.

What is a workplace exposure limit: Table of contents

Click on a specific section below to easily navigate to that area:

A brief background on exposure limits

The concept of Occupational exposure limits originated in 1883 from German scientist Max Gruber. Gruber studied himself and laboratory animals reporting the effects of carbon monoxide at different air concentrations.

In 1886, Karl Bernhard Lehmann began to develop a database of exposure limits, growing it over the course of 50 years.

A significant leap forward came in 1946 with the first ‘systemic collection of modern OELs’ by the American Conference of Governmental Industrial Hygienists (ACGIH), with an emphasis on adopting uniform rules and regulations.

In addition to being much more tolerant of risk, these historical limits had the disadvantage of focusing almost exclusively on setting exposure levels that“minimise or prevent significant acute toxicity as indicated by the occurrence of gross abnormalities after relatively short-term exposures.”

While the scientific method applied today for the development of OELs is much more rigorous, there are still significant challenges that have been present since these earliest attempts. These include a lack of global harmonisation – there can be a large variance in the levels between one country and another.

This can make it difficult for organisations operating in multiple jurisdictions to remain compliant. Imagine a business has operations in 2 countries that require significantly different OELs for working with the same substance. Should the organisation as a whole adhere to the stricter limit? Or is meeting the local legal requirement the priority? In an increasingly globalised world, it is likely that these are questions that many organisations will have to contend with.

Workplace exposure limits (UK)

In the UK, workplace exposure limits are governed by the Health and Safety Executive, under the Control of Substances Hazardous to Health (COSHH) regulation. The HSE defines exposure to a substance as: “uptake into the body by; breathing fume, dust, gas or mist, skin contact, injection into the skin, swallowing.”

WELs are averaged over a specified period, or time-weighted average (TWA). These can be broken down into 2 categories:

- Short Term Exposure Limits (STELS), 15 minutes

- Long Term Exposure Limits, 8 hours

If substances are classified as carcinogens, mutagens or asthmagens, then the exposure must be controlled to ‘as low as reasonably practicable (ALARP)’.

The HSE maintains a list of 500 substances subject to WELs, known as the EH40, with the most recent edition taking effect in 2020.

Occupational exposure limits (EU)

Within the EU, OELs can be divided into 2 categories, community OELs and national OELs. Community OELs are set by the European Agency for Safety and Health at Work (EU OSHA) in conjunction with the European Chemicals Agency (ECHA) and various sub-committees and working groups.

As with WELs, OELs are averaged over STELs of 15 to 30 minutes and TWAs over an 8-hour work day.

In Ireland, the list of OELs is maintained by the Health and Safety Authority (HSA), a list of which can be found in the HSA Code of Conduct here.

Here are a selection of other terms and definitions associated with OELs:

Indicative Occupational Exposure Limit Values (IOELV) – defined by EU OSHA as “health-based, non-binding values, derived from the most recent scientific data available and taking into account the availability of reliable measurement techniques”.

EU Member States must establish a national exposure limit value for chemical substances with IOELVs, which takes into account the EUs indicative value.

Binding Occupational Exposure Limit Values (BOELV) – BOELVs take into account socio-economic and technical feasibility factors, unlike IOELVs.

For BOELVs, EU Member States must “establish a corresponding national binding OEL value which can be stricter but cannot exceed the Community limit value.”

Biological Limit Values (BLV) – defined by EU OSHA as “reference values for the evaluation of potential health risks in the practice of occupational health.”

How are WELs/ OELs set by regulatory authorities?

In the UK if there is a proposal to introduce or revise a WEL, it generally follows a four-step process:

- Substance is assessed by relevant experts, who include an economic assessment.

- The scientific basis for introducing/updating a WEL is independently reviewed by the Workplace Expert Health Committee (WHEC)

- Public consultation is held.

- A new/ revised WEL is approved by the HSE.

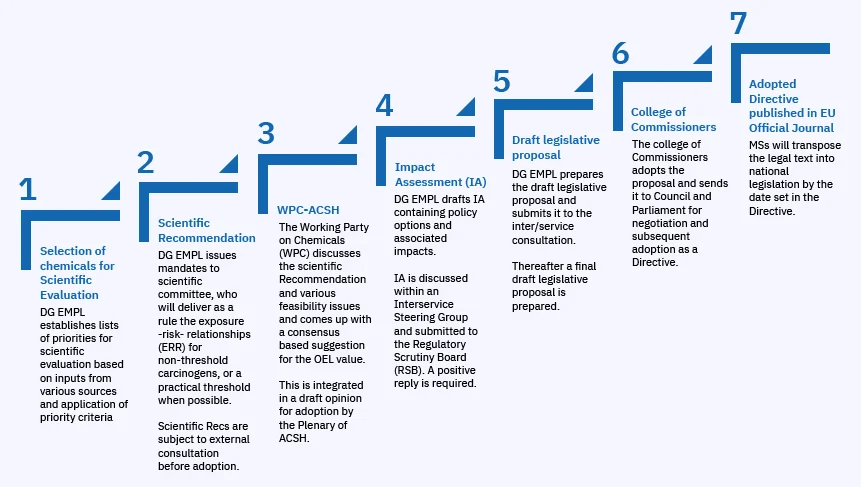

The EU also follows a stepwise process. The European Commission (DG EMPL) assigns a substance for ECHA to assess, which then goes through the following process:

Image taken from https://echa.europa.eu/oel-process.

The OELs are then implemented by individual Member States.

How can employers manage exposure limits?

Workplace and occupational exposure limits are critical to maintaining employee’s health and safety. As we have seen in the example involving chlorine gas at the beginning of this blog, there can be disastrous consequences for businesses that do not adhere to them.

The HSE investigation, in this case, found that recognised standards relating to risk assessments and staff training had not been met, despite being long established.

For any substance subject to a WEL in the UK, a detailed COSHH assessment is required which should cover all elements of handling potentially hazardous substances. It’s crucial that these assessments account for mixtures, as in the above case, as well as individual substances.

The most effective way for employers to reduce the chance of a potentially dangerous hazard scenario is to accurately monitor the value of contaminants in the air against the value provided in the EH40 or by individual EU Member States (see link above for Irelands). A useful resource for this is the GETSIS Substance database.

Regularly monitoring chemical exposures with software gives you the ability to track them long-term. It also encourages transparency with your employees by giving them access to this data. Businesses can also benefit from using digital solutions to perform and manage COSHH assessments, which can be configured to comply with global legislation including REACH, COSHH, and CLP.

EcoOnline’s Workplace Exposure Reporting software enables you to easily record single exposures or schedule regular exposures, while our COSHH Risk Assessment software reduces the administrative burden of dealing with potentially hundreds of reports.