How to manage hazardous chemicals in the workplace

Hazardous chemicals are found in many workplaces today. It is important for businesses to be aware of the potential risks associated with these chemicals, as well as how to properly manage them.

One of the most common hazards found in the workplace is the use, handling and storage of hazardous substances. COSHH management software can help eliminate these hazards, but there must be a solid understanding of rules and regulations regarding chemical management among employees.

So, what is COSHH? The Control of Substances Hazardous to Health (COSHH) Regulations have been introduced to guide employers on how to safely control the use of hazardous substances and reduce the risks that may potentially cause harm.

Hazardous substances can enter the body via inhalation, ingestion, injection or absorption. Some common types of substances hazardous to health include:

- Fumes and Smoke

- Dust

- Liquids

- Carcinogens

- Gases

- Biological Agents

Even though the workplace is safer now than it has been for the past 50 years, poisoning and other injuries due to hazardous substances still occur. Levels of exposure provide an important indicator to the hazards in the workplace environment.

Lead poisoning for example, is associated with the inhalation of lead fumes, while dust from operations such as grinding, milling, sanding and demolition can cause serious illness. The same goes for liquids, including cleaning materials and carcinogens, which can cause cancer.

In addition to this there are both gases, such as chlorine, and biological agents like bacteria, viruses, fungi and mould in ordinary workplace environments today. Chlorine, for example, is frequently used in water treatment, even though it is an extremely aggressive gas that can cause serious lung damage. Bacteria and viruses are often found in clinical waste and can cause a variety of serious illnesses.

Controlling Hazardous Substances

Exposure to hazardous substances should be prevented if it is reasonably practicable to do so. Employers should consider eliminating the process, so the hazardous substance is not needed or generated.

If this is not possible the employer should make sure the hazardous substance is substituted by a safer alternative. If this is not possible an assessment should be carried out and methods of control established using one or more of these measures:

- Enclosing the process

- Providing good ventilation

- Using systems of work and handling procedures that minimize the chances of materials spilling, leaking or otherwise escaping

- Reducing the number of employees exposed, or the duration of their exposure.

- Providing suitable training

- Using PPE (last resort)

It is the responsibility of the employer to ensure that a suitable assessment of risk to the health of employees is carried out.

Employees also have a responsibility to report any problems caused by hazardous substances used in the workplace, to their employer. Chemical reporting software can streamline this process.

You need to consider factors such as the type of chemical, the quantity of the chemical, and how it is used within your organization. It is also important to think about any potential safety hazards that may arise due to improper handling or storage of hazardous materials. Once you have assessed the risks associated with a particular chemical, you can then take steps to mitigate those risks.

Safety Signs

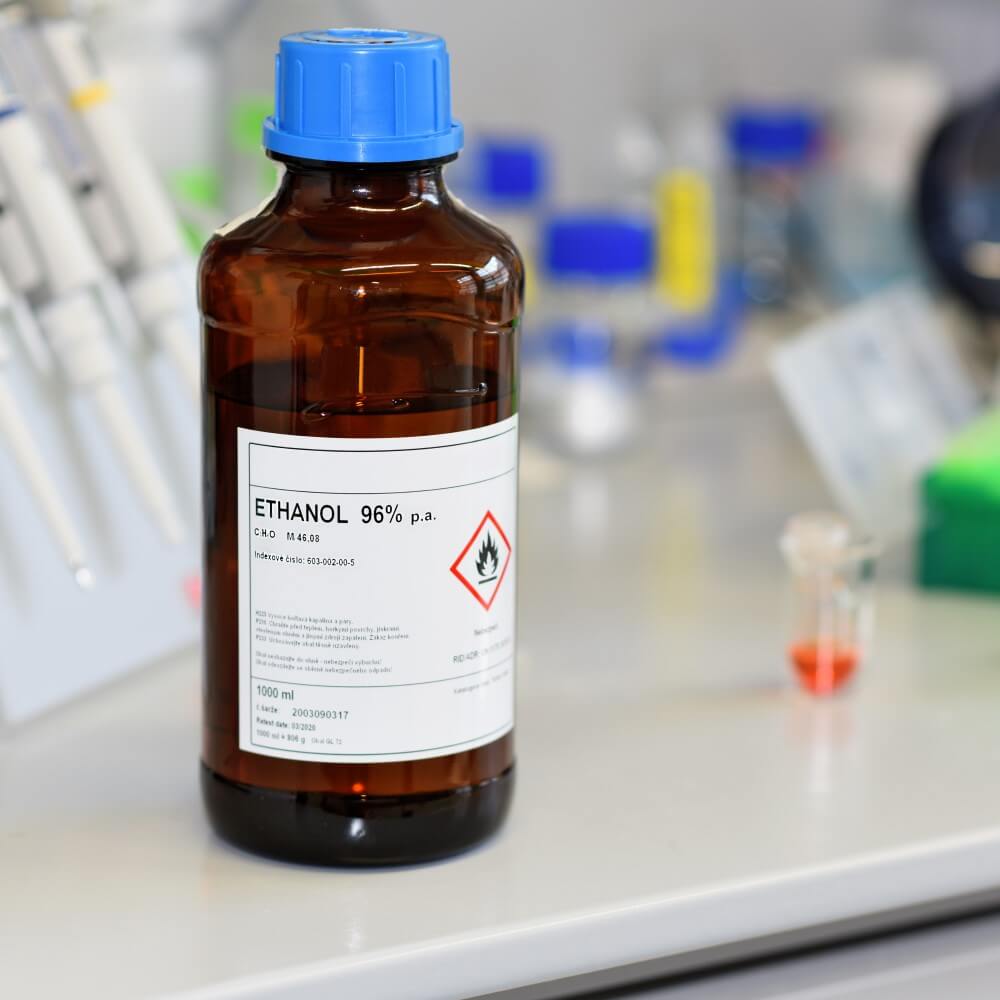

Manufacturers and suppliers must label substances and mixtures that could cause chemical hazards in accordance with the Classification, Labelling and Packaging (CLP) Regulations.

The hazardous properties from these substances can be identified from their warning label and the employer must provide a data sheet and assessment for each of them.

Adding safety signs that follow established protocols is very important. The CLP regulations provide detailed specifications for the signs that need to be put up, including the designs and the use of colors.

Training and Authorization

Employers must ensure that staff understand the risks from hazardous substances to which they could be exposed. Control methods will not be fully effective if staff do not know how to use them properly, e.g. deal with spillages, or understand the importance of reporting faults.

Staff should be made fully aware of how to use equipment and of the emergency procedures for the workplace. Authorization for the use of hazardous substances must be kept to a minimum and records should be kept, listing authorized usage personnel and the safety training they have received.

It’s important for companies to maintain a centralized register so that they know which individuals are allowed to access certain hazardous substances.

It is essential that all employees who come into contact with hazardous materials are properly trained and equipped with personal protective equipment (PPE).

Training should include instruction on proper handling procedures and safety protocols for working with these substances. Additionally, employees should always wear appropriate PPE when handling hazardous materials, such as gloves, goggles, and respirators.

It is also important for employers to provide regular refresher courses on proper handling techniques for employees who work directly with hazardous chemicals.

Proper Storage and Disposal

Companies must ensure that they take appropriate steps to ensure that all hazardous materials are stored safely and disposed of properly. All containers should be clearly labeled and kept in secure areas away from workers and other unauthorized personnel.

Additionally, it is important to ensure that all waste material generated by the use of these substances is disposed of according to local regulations. Proper disposal includes using approved disposal sites or licensed contractors if necessary.

Did you know we host FREE webinars? Click the link below to register for upcoming webinars and also view past webinars On Demand.